In the fast-paced world of electronics manufacturing, precision and quality are non-negotiable. However, amidst the intricate processes and cutting-edge technology lies a hidden threat: surface contamination. From bacteria and mold to biofilm and other contaminants, the risk of surface contamination poses unique challenges to electronics manufacturers. But fear not, because Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection is here to revolutionize the way we approach cleanliness and hygiene in electronics manufacturing.

Recent studies have highlighted the prevalence and impact of surface contamination in electronics manufacturing facilities. According to research published by the International Journal of Environmental Research and Public Health, surface contamination in electronics manufacturing can lead to product defects, reduced reliability, and even system failures. Traditional cleaning methods often fall short in addressing these contaminants, underscoring the need for advanced detection technologies like Cleanspect™.

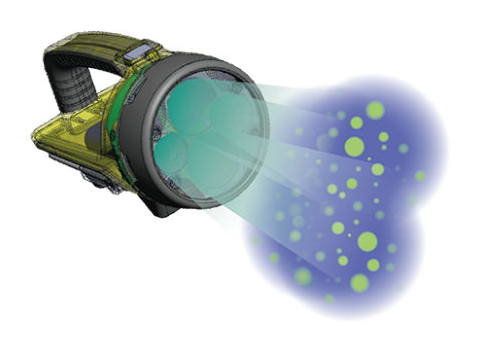

Electronics manufacturing presents a unique set of challenges when it comes to surface contamination. The sensitive nature of electronic components makes them susceptible to damage from even minor contaminants, leading to costly defects and production delays. Additionally, the intricate design of electronic devices creates hidden crevices where contaminants can lurk undetected, further exacerbating the risk. Cleanspect™ technology offers a comprehensive solution by providing real-time, multispectral fluorescence imaging that identifies and quantifies surface contamination with unmatched precision.

At Cleanspect™, we’re committed to empowering infection control and prevention specialists with the tools they need to maintain pristine cleanliness in electronics manufacturing facilities. By inspecting surfaces and detecting surface contamination such as bacteria, mold, biofilm, and other contaminants, we enable specialists to implement targeted sanitation protocols that mitigate against these risks. With Cleanspect™, you can ensure the reliability and quality of your electronic products while safeguarding public health.

As the demand for electronic devices continues to soar, maintaining impeccable cleanliness in manufacturing facilities is more critical than ever. Are you ready to use state-of-the-art contamination detection technology to elevate your electronics manufacturing processes? Join us in our mission to revolutionize industrial hygiene and ensure the integrity of electronic products worldwide. How can we help you optimize your surface sanitation protocols today?

Emergency Medical Services (EMS) are at the front line of the healthcare system’s emergency response. As first-responders or patient transporters, they can encounter infectious disease, blood, and bodily fluids on a daily basis.

In order to ensure the safety of their patients, their ambulances, medevacs, and apparatuses must be effectively cleaned and sanitized to prevent contamination and the spread of infection. Bactiscan Cleaning Verification enables EMS providers to quickly and efficiently measure the effectiveness of cleaning practices and offer actionable data to alert staff of problem areas, evaluate cleaning methods, and set goals for improvement.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge the electronic manufacturing industry uses to prevent contamination, product defects, and failure.