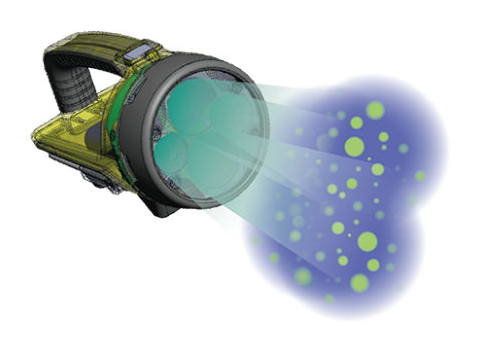

Imagine a cutting-edge aerospace facility where the margin for error is non-existent. Each component must be impeccably clean to ensure the highest standards of performance and safety. Enter Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection. This innovative technology revolutionizes how we detect and manage contamination in cleanrooms and safety cabinets, ensuring that even the smallest particles are identified and removed.

Products sensitive to contamination, such as aerospace parts, must be assembled in certified cleanrooms to ensure their integrity and functionality. Cleanspect™ excels in detecting particles as small as 30 μm, which are invisible to the human eye, thereby preventing contamination. This capability is crucial for maintaining the stringent standards required in these high-stakes environments.

A biosafety cabinet (BSC) is a crucial tool in laboratories working with potentially hazardous materials. Proper cleaning and maintenance of these cabinets are essential to prevent cross-contamination and ensure the safety of lab personnel.

Microbiological Safety Cabinets (MSCs) are often used by multiple researchers throughout the day, making stringent cleaning protocols vital. Stainless steel surfaces, although corrosion-resistant, require careful cleaning to maintain their integrity and prevent corrosion. Traditional cleaning methods using alcohol-based disinfectants or quaternary ammonium salts (QUATS) are not foolproof. Cleanspect™ enhances these protocols by providing non-invasive detection of bacteria, biofilms, mold, and organic residues.

Biofilms, complex assemblies of microorganisms, are a common source of persistent contamination. They can form on various surfaces within cleanrooms and safety cabinets, posing significant risks. Cleanspect™ uses AI-powered UV-based multispectral fluorescence imaging to detect biofilms and their unique spectral signatures, ensuring thorough decontamination.

Surface disinfection compatibility is crucial to prevent damage that can harbor microbes. Incompatible disinfectants can cause pits, cracks, and fissures, leading to MIC and making effective disinfection difficult. Cleanspect™ helps monitor surface conditions and identify early signs of corrosion, allowing for timely intervention and mitigation.

In addition to its applications in the food industry, Cleanspect™ is invaluable in identifying biofilms in spacecraft assembly cleanrooms. These cleanrooms are critical environments where stringent microbial control is essential. Studies have shown that biofilms, which can harbor antibiotic-resistant bacteria (ARB) and antibiotic-resistance genes (ARGs), are often found in these cleanrooms despite rigorous cleaning protocols.

Cleanspect™ can detect these biofilms, highlighting areas that may have been compromised by incompatible cleaning agents and enabling targeted interventions to prevent contamination. This capability is crucial for maintaining the integrity of spacecraft components and ensuring astronaut safety.

Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection is a game-changer for maintaining cleanrooms and safety cabinets. By effectively detecting and visualizing biofilms and other contaminants, Cleanspect™ ensures the highest standards of cleanliness, protecting both products and personnel. How will Cleanspect™ enhance the cleanliness and safety of your facility?

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge that cleanrooms and safety cabinet facilities use to prevent contaminations.