Step into the world of grains, where golden fields sway in the breeze and the promise of sustenance lies within each kernel. Yet, amidst the abundance, there lurks a silent threat: surface contamination. In the vast expanse of the Grains Industry, ensuring food safety is paramount. That’s where Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection technology comes in, shedding light on hidden dangers and revolutionizing grain safety.

Within the Grains Industry, from storage silos to processing plants, surfaces can harbor microscopic contaminants that evade traditional cleaning methods. But with Cleanspect™, we peer beyond the surface, detecting biofilm on filling machines and other equipment, and unveiling the presence of bacteria, mold, and other contaminants that pose risks to food safety.

Recent studies published by leading food safety industry publications highlight the importance of fluorescence image-guided surface contamination detection in the Grains Industry. According to research from the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA), advanced detection technologies like fluorescence imaging play a crucial role in safeguarding grain quality and minimizing the risk of food-borne illnesses.

At Cleanspect™, we empower infection control and prevention specialists with the tools they need to safeguard the integrity of grains. By inspecting Grains Industry surfaces and detecting surface contamination, our technology enables specialists to implement targeted cleaning and sanitation protocols, ensuring that grains destined for consumption are free from harmful contaminants.

As we navigate the complexities of the Grains Industry, one thing remains clear: vigilance is key to ensuring food safety. With Cleanspect™ technology, we illuminate the path to safer grain production, providing infection control and prevention specialists with the insights they need to protect public health. Are you ready to join us in our mission to ensure the safety and integrity of grains?

Step into a brighter future for grain safety with Cleanspect™. Together, let’s shine a light on surface contamination and pave the way to a safer food supply.

Grain is a relatively low-risk food product; however, there must be a priority on production equipment and cleaning protocols to ensure safety and customer satisfaction. In addition, grain products have not been exempt from recalls for microbial contaminations originating in the supply chain.

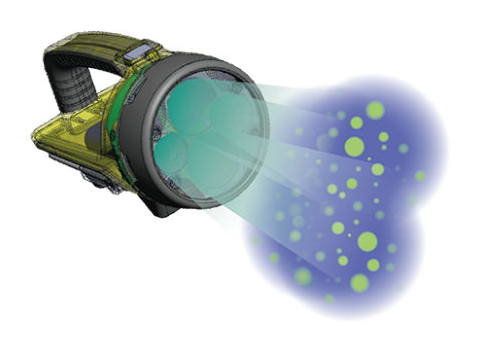

Keeping your sanitation program within budget is easy with Cleanspect™’s sanitation monitoring and pathogen detection system. We offer a device that uses advanced UV-based technologies and multispectral imaging to detect specific pathogens on surfaces and prevent bacterial contamination and other potentially harmful contaminants.

The information provided by Cleanspect™ can help make product release decisions with more confidence, thus minimizing re-tests, employee training, and time to market.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge that the grains industry uses to prevent contaminations and food-borne illnesses.