Step into the world of poultry production, where every step of the process is meticulously managed to ensure the safety and quality of poultry products. Amidst the bustling activity of hatcheries, farms, and processing plants, maintaining stringent hygiene standards is paramount. Here’s where Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection comes into play, revolutionizing safety protocols in the poultry industry.

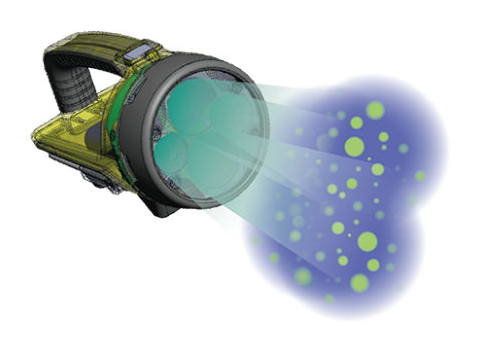

In the poultry industry, where surfaces come into contact with raw meat and processing equipment, the risk of surface contamination is ever-present. With Cleanspect™ technology, we shine a light on the unseen, detecting biofilm on filling machines and other equipment, and identifying surface contaminants such as bacteria, mold, and biofilm. By uncovering these hidden threats, we empower infection control and prevention specialists to take targeted action to mitigate risks and ensure the safety of poultry products.

Recent studies published by leading food safety industry publications highlight the importance of fluorescence image-guided surface contamination detection in the poultry industry. According to research from the United States Department of Agriculture (USDA) and the National Chicken Council (NCC), advanced detection technologies like fluorescence imaging are crucial for upholding safety standards and preventing food-borne illnesses in poultry products.

At Cleanspect™, we understand the critical role that infection control and prevention specialists play in safeguarding poultry production. By inspecting poultry industry surfaces and detecting surface contamination, our technology provides specialists with the insights they need to implement targeted cleaning and sanitation protocols. From hatcheries to processing plants, we work hand-in-hand with industry professionals to ensure the highest standards of hygiene and safety.

As we strive to meet the growing demand for poultry products, safety remains our top priority. With Cleanspect™ technology, we’re paving the way for a safer future in poultry production, empowering infection control and prevention specialists with the tools they need to protect public health. Are you ready to join us in our mission to ensure the safety and integrity of poultry products?

It is a challenging task to ensure your customers receive quality poultry. To accomplish this task, poultry processors can look to Cleanspect™ because it is an accurate, reliable, easy-to-use, fast, and affordable food-safety monitoring device.

It effectively monitors sanitation to detect residues, and pathogens on surfaces.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge that the poultry industry uses to prevent contaminations and food-borne illnesses.