Welcome to the forefront of food safety innovation. At Cleanspect™, we’re revolutionizing the way the egg industry approaches cleanliness and hygiene. Join us as we explore the groundbreaking application of our AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection technology in egg production facilities, ensuring the highest standards of safety and quality.

Unveiling Hidden Contaminants in Egg Production

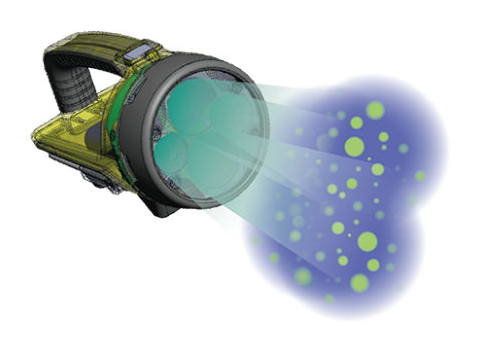

In the bustling world of egg production, maintaining impeccable hygiene is paramount. However, conventional cleaning methods often fall short in detecting microscopic contaminants that can compromise food safety. That’s where Cleanspect™ comes in. Our cutting-edge technology utilizes fluorescence imaging to uncover surface contamination, including elusive biofilm, on filling machines and other equipment. This empowers infection control and prevention specialists to take proactive measures against food-borne illnesses.

Harnessing the Power of Advanced Contamination Detection

Recent studies published by reputable food safety industry publications highlight the importance of fluorescence image-guided surface contamination detection in egg production. According to research conducted by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), advanced detection technologies like fluorescence imaging have significantly improved hygiene practices in the egg industry, reducing the risk of contamination-related issues. These findings underscore the critical role of innovative solutions in enhancing food safety protocols.

Empowering Infection Control Specialists

At Cleanspect™, we’re dedicated to supporting infection control and prevention specialists in their mission to uphold the highest standards of safety. Our technology not only identifies surface contamination but also provides real-time insights into cleaning and sanitation protocols. By detecting bacteria, mold, biofilm, and other contaminants, Cleanspect™ enables specialists to implement targeted cleaning measures, mitigating the risk of food-borne illnesses and ensuring consumer safety.

Conclusion: A Safer Future for Egg Production

As the egg industry continues to prioritize safety and quality, Cleanspect™ stands as a beacon of innovation and reliability. Are you ready to take your egg production facility to the next level of cleanliness and hygiene?

Join us in embracing the future of egg safety with Cleanspect™. Together, we can ensure that every egg meets the highest standards of quality and purity.

If your facility handles shell eggs, liquid, dried, or frozen eggs, Cleanspect™’s rapid hygiene monitoring device offers an economical and rapid method for identifying and monitoring contamination.

We offer a simple, easy-to-use device that ensures clean and safe processing environments with accuracy and consistency every time. Utilizing its sophisticated, yet easy-to-use innovative UV-based technology, Cleanspect™ can detect a wide range of potential pathogens on surfaces.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge, the egg industry uses to prevent contamination and foodborne. illnesses