Dairies are a vital part of the food industry, providing us with a range of dairy products from milk to cheese and yogurt. Ensuring the safety of dairy products is paramount, as any contamination can lead to severe health risks for consumers and significant economic losses for dairy producers. Traditional methods of detecting processing surfaces and equipment contaminants can be time-consuming and may not always be effective. That’s where fluorescence image-guided food safety solutions step in, offering dairies a cutting-edge technology to enhance safety and quality assurance.

The dairy industry faces several unique challenges when it comes to food safety:

Dairy products are susceptible to contamination by various microorganisms, including bacteria, molds, and yeasts. Pathogens like E. coli and Salmonella are of particular concern.

Dairy processing equipment provides an ideal environment for biofilm formation. Biofilms can harbor harmful bacteria, making their detection and eradication crucial.

Maintaining product quality is not only essential for safety but also for consumer satisfaction. Any deviation in taste, texture, or appearance can result in product recalls and reputational damage.

The dairy industry is subject to strict regulations and standards to ensure the safety of dairy products. Non-compliance can lead to legal issues and recalls.

Given these challenges, it’s evident that dairy producers require advanced tools to address food safety effectively.

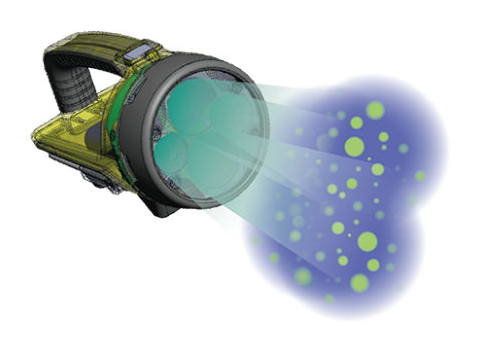

AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection food safety solutions, such as Cleanspect™, offer a revolutionary approach to ensuring food safety in the dairy industry. Here’s how it works:

Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection technology is at the heart of these solutions. It utilizes specialized wavelengths of UV light to interact with fluorescence associated with regions of bacteria, biofilm, mold, and proteins in contaminants, causing them to fluoresce or emit light.

One of the most significant advantages of Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection imaging is its speed. It provides real-time results, allowing for immediate action when contaminants are detected.

Perhaps one of the most critical challenges for the dairy industry is the presence of biofilms. Biofilms can form on dairy processing equipment, making traditional surface inspection and cleaning methods ineffective. Cleanspect™ fluorescence imaging can reveal these hidden biofilms, ensuring thorough cleaning and preventing product contamination.

Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection device scans entire surfaces, leaving no area uninspected. This level of comprehensiveness is crucial for detecting contaminants in dairy processing facilities.

Unlike some traditional methods that involve the use of chemicals, Cleanspect™ fluorescence imaging is environmentally friendly. It relies on our advanced UV light technology and does not require consumables, making it cost-effective and sustainable.

Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection has a wide range of applications in dairy processing:

Milk is a primary raw material in the dairy industry. Ensuring that processing surfaces are free from harmful microbes is essential. Cleanspect™ imaging can be used to detect contaminants on surfaces and equipment before processing.

Cheese production involves several steps where contamination can occur. From curdling to aging, fluorescence imaging can help identify and eliminate surface contaminants, ensuring product safety and quality.

Yogurt is another dairy product susceptible to contamination. Real-time detection of contaminants on processing surfaces using Cleanspect™ ensures that only safe yogurt reaches consumers.

Cleaning dairy processing equipment is a challenge due to the risk of biofilm formation. Cleanspect™ imaging can reveal the presence of biofilms, allowing for targeted cleaning and disinfection.

Cleanspect™ can also be used for quality control purposes, ensuring that dairy facilities meet the desired standards for cleanliness and hygiene.

The adoption of Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection food safety solutions offers several benefits for dairies:

Real-time detection of contaminants ensures that only safe dairy products reach consumers, reducing the risk of foodborne illnesses.

By detecting and eliminating biofilms, dairies can prevent product contamination and maintain product quality.

Meeting regulatory standards is crucial for dairies. Cleanspect™ helps ensure compliance with food safety regulations.

Preventing contamination incidents through early detection results in significant cost savings compared to recalls and legal expenses.

Fluorescence imaging is an environmentally friendly technology that aligns with sustainability goals.

To reap the benefits of Cleanspect™ AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection food safety solutions, dairies can follow these steps:

Begin with an assessment of your dairy processing facility’s specific needs and potential contamination risks.

Proper training of staff on the use of fluorescence imaging technology is essential for effective implementation.

Integrate fluorescence image-guided solutions into your food safety protocols and quality control processes.

Regularly monitor and inspect dairy processing equipment and surfaces using Cleanspect™ to ensure ongoing food safety.

The dairy industry plays a vital role in providing consumers with nutritious and delicious products. Ensuring the safety and quality of dairy products is not just a responsibility; it’s a commitment to public health and satisfaction. Cleanspect™ empowers the dairy industry to meet this commitment effectively. By detecting surface contaminants in real-time, preventing bacteria, mold, and biofilm formation, and maintaining regulatory compliance,

As dairy products reach consumers in every region of the world, the maintenance of product safety and quality is a top priority. Cleanspect™’s rapid surface scan is easy to perform, affordably priced, and provides microorganism detection and cleaning verification in seconds.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge, the dairy industry uses to prevent contamination and food-borne illnesses.