Cleanspect™ Fluorescence Image-Guided Surface Contamination Detection

Invisible To Visible And Beyond Visible!

Cleanspect™ assures a higher level of cleanliness across the cannabis industry by detecting bacteria, biofilm, and mold on surfaces, protecting crops, consumer safety and health.

As states establish regulations to ensure pathogen-free cannabis products, Cleanspect™ delivers the technology each grower, processor, and dispensary needs to detect and prevent microbial contamination. Discover Cleanspect™’s UV-based technology for the detection of powdery mildew, aspergillus, and other pathogens on surfaces in minutes.

Environmental Pathogen Monitoring Is Your "smoke alarm"!

In a rapidly expanding and increasingly regulated industry such as cannabis, screening tools to detect microbes are becoming increasingly crucial.

While screening has focused primarily on screening raw cannabis products, little attention has been paid to screening the actual facilities where that product is processed, which has the potential to be a contaminant source for the final product.

It is important to recognize that a contaminated product contact surface is your “smoke alarm” for contaminated products.

Environmental surveillance is increasingly implemented in the cannabis industry due to increased regulations and crop loss, from microbial contamination.

Pathogens are always a concern in cannabis production facilities, as they indicate a potential reservoir of contaminating organisms.

Furthermore, these pathogenic organisms may pose a significant threat to both human health and cannabis products.

Cannabis pathogens present in cannabis growing and processing facilities may increase the risk of cannabis disease, which could lead to crop losses and rejected cannabis products.

Not only are these concerns prevalent in cannabis operations but in food and pharmaceutical production as well.

Cannabis Environmental Pathogen Testing

The rapidly expanding cannabis regulations require higher and higher levels of sophisticated microbial contamination testing, which can be expensive.

Cannabis products that are being tested for microbial contamination are typically submitted without a high degree of confidence that they will meet existing regulations. This lack of confidence frequently leads to the harsh reality of product failure. If this high-value product fails microbial testing, it cannot be sold.

This leads to investment losses, grower losses, processor losses, manufacturing losses, and less product on dispensary shelves that is safe for patients.

Unfortunately, most cannabis growers become keenly aware of the need for environmental testing after the first loss and in their search for crop loss prevention in the future.

A high-value crop like cannabis must be protected from testing failures – otherwise, brands, companies, products, and investors can suffer great losses.

As a result, environmental monitoring has become one of the most important “best practices” in cannabis production.

Cleanspect™ Cannabis Environmental Pathogen Monitoring And Testing Solutions

/arc-anglerfish-tgam-prod-tgam.s3.amazonaws.com/public/634CABK3TZHE7CYADHN4IBYEBU.JPG)

We offer Cleanspect™’s innovative technology to solve this vexing problem for cannabis growers, processors, and dispensaries. The solution is to use Cleanspect™ to monitor relevant areas within grows, processing, manufactures, and dispensaries for microbial surface contamination.

Using traditional culture methods for environmental pathogen monitoring is challenging in terms of time and expense.

Utilizing the Cleanspect™ Cleanspect™ Fluorescence Image-Guided Surface Contamination Detection system can definitively detect surface contamination in a fraction of time and cost, thus making cannabis environmental monitoring a practical reality.

Thus producers, processors, and dispensaries can quickly detect contamination, before harvesting, processing, and dispensing products.

This enables producers to mitigate any contamination issues before submission of products to testing labs.

Cleanspect™ provides growers, processors, and dispensaries the tool to perform this type of routine environmental pathogen monitoring in a timely and cost-effective manner.

Food Safety Solutions

Due to the potential negative impacts of microbial contamination on cannabis production and processing facilities, practices to reduce risk must be developed, diligently followed, and maintained.

Cleanspect™ environmental monitoring system can be used to continuously monitor and screen facilities for microbial contamination, which is an important component of risk reduction.

Despite being largely harmless, some of the microorganisms detected in continuous surveillance can pose health risks to humans and to cannabis products.

It is important to perform initial testing to detect and identify any contaminating organisms that may be present within that facility.

These baseline test results can be used to compare subsequent screening results and verify that decontamination methods are effective.

Furthermore, Cleanspect™ can confirm contamination sources, validate the cleanliness of the facility, as well as identify any new instances of contamination.

Cleanspect™ Cleaning Verification And Validation System

Microbial contamination could go undetected without environmental screening, endangering the yields of cannabis and human health.

The use of Cleanspect™ for screening at cannabis facilities can reduce contamination rates, modify decontamination procedures as needed, and ensure that facilities are monitored to ensure rapid detection of recurrence of contamination.

Cleanspect™ can be used to evaluate potential microbial contamination within cannabis production and processing facilities by screening the environmental surfaces for pathogens.

Cleanspect™ enables rapid detection of surfaces that are contaminated with pathogens, so you can protect your product, your customers, and your business!

HVAC And Dehumidifier Preventative Control

Dehumidifiers and HVAC systems can serve as microbe reservoirs. It is ideal to clean between each growing cycle or as your local jurisdiction requires.

When crops are moved from one room to another, the HVAC system must also be clean.

Surfaces susceptible to contamination by bacteria and mold include air filters, drain pan(s), airstream coils, P-traps, outdoor air louvers, and fan wheels.

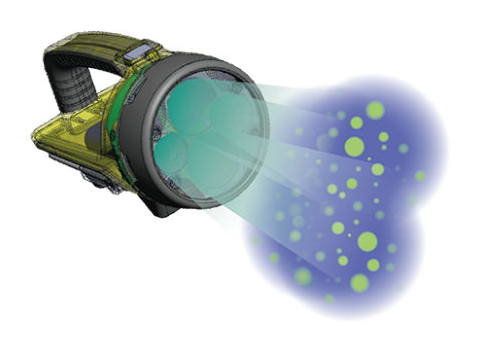

Cleanspect™ Fluorescence Image-Guided Surface Contamination Detection UV technology enables illumination of areas that are otherwise hard to access.

By illuminating these surfaces, Cleanspect™ can detect bacteria, biofilm, mold, and other contaminants.

Dehumidifiers, often have multiple sets of air filters to prevent mold spores from circulating in the moist air.

Typically, dehumidifier coils are several inches deep, making it difficult to clean them thoroughly.

Further, the items caught by the filters from one crop can contaminate subsequent crops.

Coils are also used in dehumidifiers, such as evaporator, re-heat, and outdoor condenser coils. These coils can harbor pathogens, which can cause contamination.

These coils can be inspected for bacteria, biofilms, and mold using Cleanspect™, preventing product contamination.

Cleanspect™ Cleaning Verification And Validation System

According to Yamashiro(2019), for environmental monitoring to be effective for cannabis growers and processors, it should utilize “SMART” tests. SMART tests include:

- Simple – straightforward and easy to use with facile interpretation and reporting of test results

- Money-conscious – overall low cost of testing which encompasses not only reagents or kit, but also dedicated equipment, facilities, and specially trained laboratory staff to run the tests

- Accountability – provide actionable results to understand the location and potential sources of contamination which hold accountable the individuals and processes responsible for the cleanliness of the affected area(s) within the facility

- Reliability – this is paramount to instill confidence that the results are accurate, informative, and truly actionable

- Timely – early detection is necessary to implement mitigation actions early to prevent systemic contamination of the entire facility and product failures

Cleanspect™ delivers the first UV-based SMART testing platform to reshape the Cannabis industry, by providing results immediately.

Cleanspect™ satisfies those criteria and is truly a "SMART" testing device.

Food Safety Solutions

Cleanspect™ provides proactive approaches to detect microbial contamination of surfaces and environmental monitoring of surfaces within cannabis cultivation and processing facilities. Using the Cleanspect™ SMART tester, it is possible to provide management of a facility with early detection of a contamination breach and implement mitigation measures to eradicate the contamination, before it becomes systemic and large quantities of highly valued products are compromised.

Cleanspect™ Sets The Standard In Surface Pathogen Detection.

Immediately detect surfaces contaminated with multiple pathogens (including powdery mildew and gray mold).

- Perform an unlimited number of scans per day, thanks to advanced UV-based technology that enables industry-leading throughput.

- Establish a cannabis industry best practice that reduces crop losses and costs.

- Adopted by hundreds of healthcare and food industry facilities to replace outdated testing!

Microbial detection for growers and processors serving the cannabis industry is critical to ensure a safe and healthy cannabis industry. Cleanspect™ industry-leading throughput system ensures unlimited scans can be performed per day. It’s one more way Cleanspect™ delivers a cleaner, more profitable cannabis future.

Cleanspect™ Prevent High-Value Cannabis Crop loss with Innovative Environmental Monitoring Technology

Cleanspect™ Sets The Standard In Surface Pathogen Detection

Microbial detection for growers and processors serving the cannabis industry is critical to ensure a safe and healthy cannabis industry. Cleanspect™ industry-leading throughput system ensures unlimited scans can be performed per day. It’s one more way Cleanspect™ delivers a cleaner, more profitable cannabis future.

Cleanspect™ Prevent High-Value Cannabis Crop Loss with Innovative Environmental Monitoring Technology. It offers many advantages over traditional methods and technologies for microbial detection. Compared to traditional methods and technologies.

Cleanspect™’s decades of scientific advancement in Fluorescence Imaging make it a leading bacteria and biofilm surface contamination detection system. Cleanspect™ significantly reduces both time and cost compared to traditional surface microbial contamination detection methods.

It’s Simple

Use Cleanspect™ to illuminate the surfaces of equipment, work tables, vents, windows, trays, or any other surface in your facility. Its ultra-fast pathogen detection system identifies the exact location of bacteria, Biofilm, mold, and other surface contaminants.

It’s Fast

Immediately see where to sample, and clean with the guidance of fluorescence imaging. Cleanspect™ requires no lab time and space, and returns definitive results immediately, at a fraction of traditional bioluminescent swab test costs. It eliminates many steps from conventional surface microbial testing methods, dramatically reducing time and expenditure.

It’s Scalable

Cleanspect™ advanced UV technology is utilized to detect bacteria, biofilm, mold, and multiple other pathogens on surfaces, and can perform an unlimited number of scans in a single day, at no additional cost.

It's Replicable

Cleanspect™ environmental surface contamination detection and preventative control monitoring system provides consistent, replicable results, even in microbial organisms that are difficult to detect, and on irregular and difficult-to-access surfaces.

It’s Cost-Effective

Cleanspect™ well-priced and does not use any consumables. Perform an unlimited number of scans without consumables and at no additional cost. The real cost efficiencies come from the money saved by reducing product loss to contamination and reducing cannabis-borne illnesses. The cleaner your facility, the cleaner your yield.

It’s Precise

Cleanspect™ allows for targeted sampling and cleaning by seeing exactly where fluorescent bacteria are located. Immediately see where to sample, and clean with the guidance of fluorescence imaging.

It’s Eco-Friendly

Cleanspect™ does not use any consumables, harmful dyes, gels, chemicals, or gases. Therefore, it does not have adverse environmental effects or add carcinogenic, allergenic harmful additives to our food.

Creating A Cleanspect™ Clean Cannabis Industry

You can avoid potential economic losses associated with 30 percent of cannabis being contaminated and wasted. Detecting surface pathogens with Cleanspect™ is simple and efficient, which ensures a clean, efficient operation. One simple click of a switch can help you safeguard your grow and your business.

Contamination from inadequate sanitation, biofilm residue, and allergens in cannabis manufacturing facilities can lead to spoiled products, ingredient contamination, and dissatisfied customers.

Cleanspect™’s sanitation monitoring system is an easy-to-use device that harnesses the power of UV-based Fluorescence Image-Guided Surface Contamination Detection technology to detect surface pathogens, including bacteria, mold, biofilm, and residues that are troublesome to the cannabis industry.

Cleanspect™ surface pathogen detection system can also help verify that cleaning procedures, sanitation chemicals, and personnel effectively remove contamination before production starts.

With Cleanspect™, you can ensure your facility and equipment are safe and clean, allowing you to stand out from the competition. Standardized government regulations are still evolving, so get ahead of the curve and be audit-prepared when the time comes.

Cleanspect™ SMART auditing advanced UV lamp identifies the exact location of surface pathogens, enabling immediate mitigation, preventing compliance delays and, more importantly, avoiding crop losses.

Cleanspect™ provides a higher level of cleanliness to the cannabis safety industry by immediately identifying bacteria, biofilm, mold, and other contaminants on surfaces, to prevent cannabis contamination and food-borne illnesses.

Illuminate Away Uncertainty!

The Cleanspect™ Difference

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge that the cannabis industry uses to prevent contaminations and cannabis-associated infections.