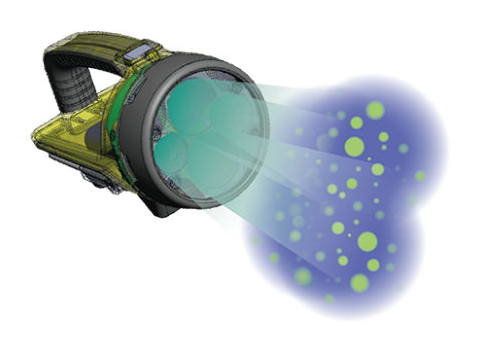

Welcome to the forefront of beverage processing safety. At Cleanspect™, we’re proud to introduce our state-of-the-art AI-Powered Multispectral Fluorescence Image-Guided Surface Contamination Detection technology, designed to revolutionize food product safety in the beverage processing industry. Join us as we explore the pivotal role of Cleanspect™ in ensuring the highest standards of cleanliness and hygiene in beverage processing facilities.

Unveiling Hidden Contaminants

In the fast-paced world of beverage processing, maintaining pristine hygiene is paramount. However, traditional cleaning methods often fall short in detecting microscopic contaminants that can compromise product safety. That’s where Cleanspect™ comes in. Our advanced technology utilizes fluorescence imaging to uncover surface contamination invisible to the naked eye, enabling proactive measures to prevent food-borne illnesses.

Insights into Cutting-Edge Contamination Detection

Recent studies published in leading food safety industry publications have highlighted the effectiveness of fluorescence image-guided surface contamination detection in beverage processing. According to findings from the Food and Drug Administration (FDA) and the Centers for Disease Control and Prevention (CDC), advanced detection technologies like fluorescence imaging have significantly reduced the risk of food-borne illnesses in beverage processing facilities. These insights underscore the importance of embracing innovative solutions to enhance food safety practices.

Empowering Infection Control Specialists

At Cleanspect™, we understand the critical role of infection control and prevention specialists in safeguarding consumer health. That’s why our technology not only identifies surface contamination but also equips specialists with real-time data to make informed decisions about cleaning and sanitation protocols. By detecting bacteria, mold, biofilm, and other contaminants, Cleanspect™ empowers specialists to maintain a hygienic environment and prevent food-borne illnesses.

Conclusion: Embracing a Safer Future for Beverage Processing

As beverage processing facilities strive to uphold the highest standards of safety and quality, Cleanspect™ stands as a trusted ally in their journey. Are you ready to elevate beverage processing safety and inspire confidence in your products?

Join us in revolutionizing beverage processing safety with Cleanspect™. Together, we can ensure that every sip is as safe as it is refreshing.

Cleanspect™ sanitation monitoring device is ideal for any beverage processor. It provides easy verification of equipment cleanliness and safety by inspecting equipment and environment surfaces to detect microbes that cause biofilm formation and product spoilage, thus ensuring the highest-level of manufacturing quality. Cleanspect™ also quickly detects product residues left on a surface after cleaning.

Cleanspect™ indicates the presence of microorganisms at low and high contamination levels, allowing easy identification of areas in which cleaning had not been effective.

Using Cleanspect™’s science-based cleaning verification and preventative control system, you can assess your cleaning outcomes to reduce beverage contamination and foodborne illnesses.

The Cleanspect™ Certified Clean program goes above and beyond the scientific knowledge that the beverage processing industry uses to prevent contaminations and food-borne illnesses.